sheet metal drawing operation is used to make

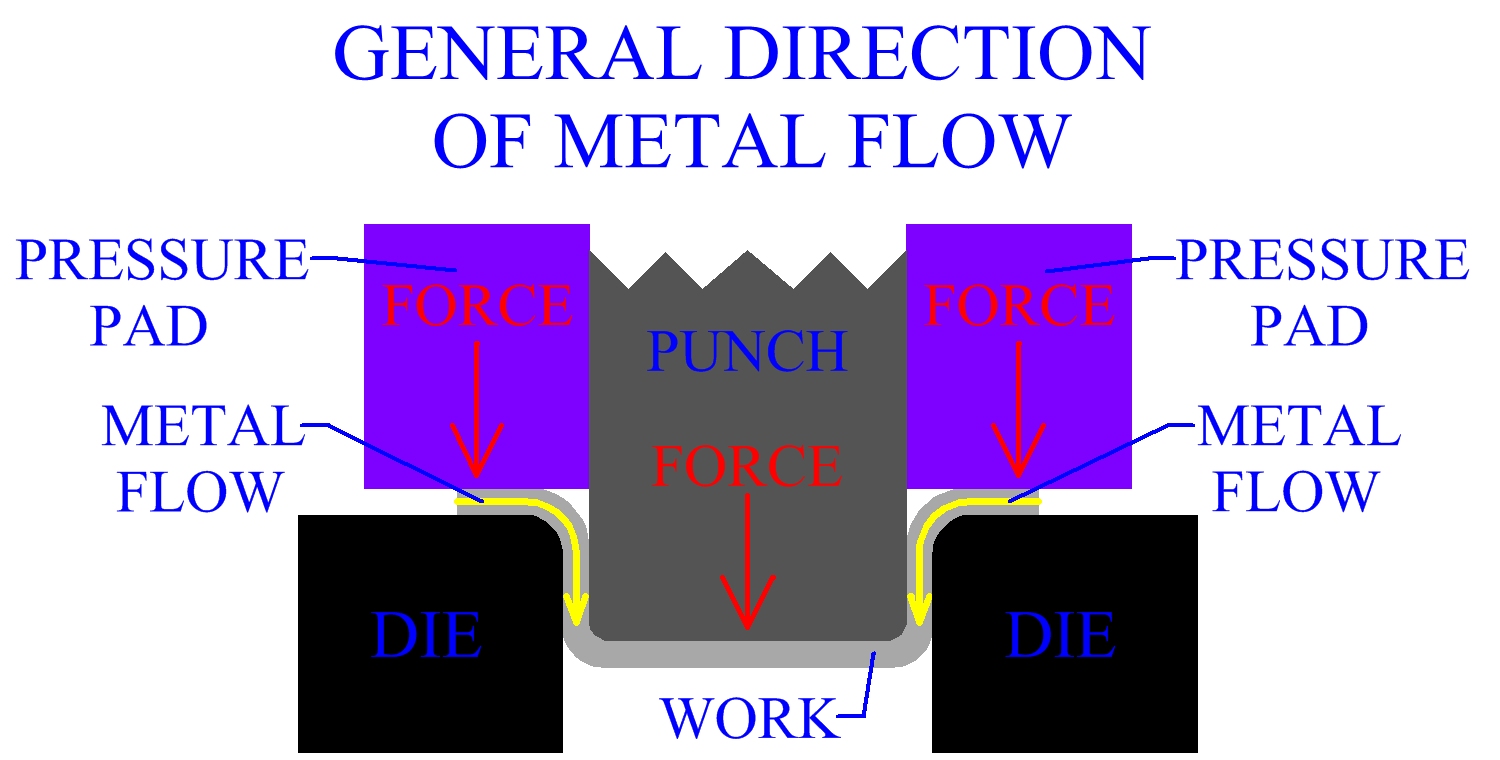

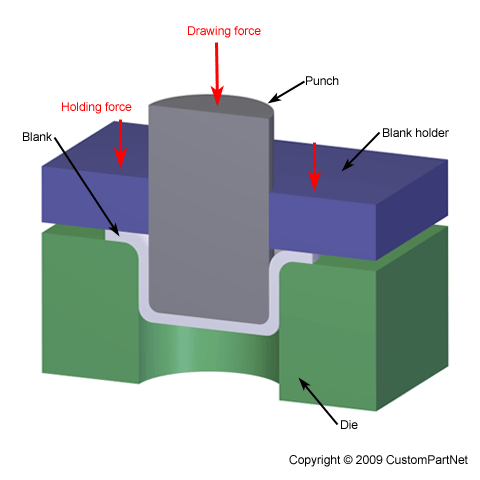

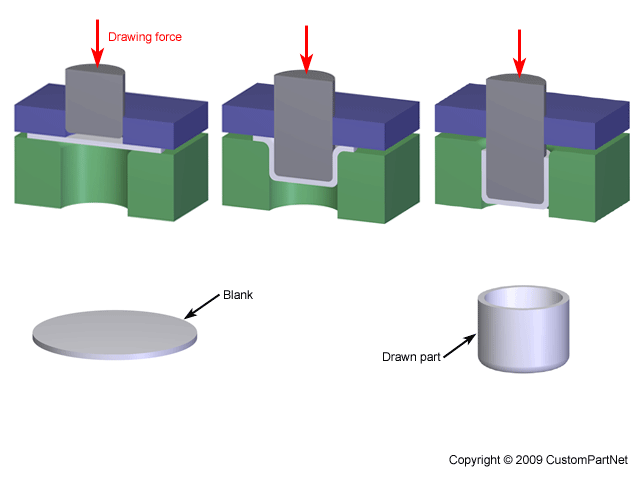

Drawing is accomplished by placing a piece of sheet metal over a die cavity and then using a punch to push the metal into the cavity. Sheet metal drawing is defined as a plastic deformation over a curved axis.

Deep Drawing An Overview Sciencedirect Topics

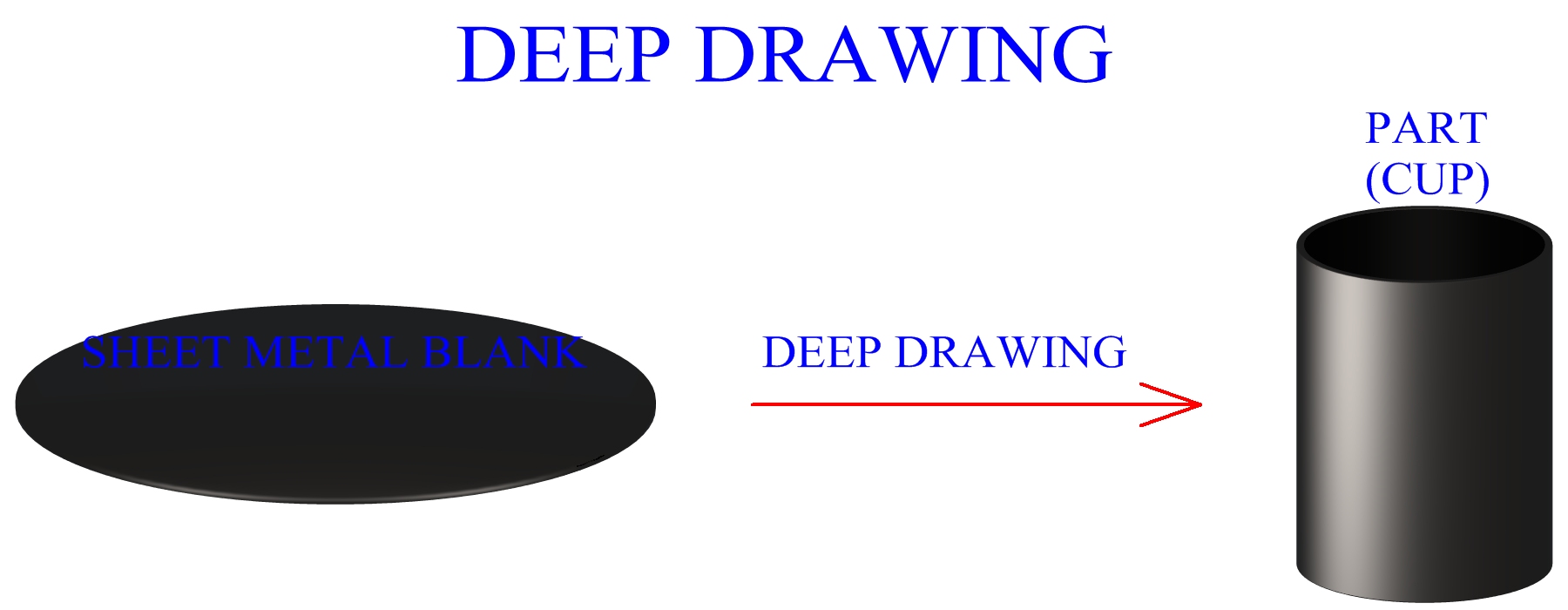

Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved an concave parts.

. Sheet is held by jaws or drawbeads at both the ends and then stretched by punch such. The punch is the desired shape of the base of the part once drawn. Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved hollow parts.

Drawing is a metalworking process which uses tensile forces to stretch metal or glass. In this article we mainly focus on sheet metal cutting operations and other two we will discuss into upcoming articles. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and pushing the metal into the cavity with a punch.

Drawing is accomplished by placing a piece of sheet metal over a die cavity and then using a punch to push the metal into the cavity. This mode is typical the material flow from the flange towards the. As the metal is drawn it stretches to become thinner to achieve a desired shape and thickness.

This process is very extensively used in the automobile industry to achieve a high production rate. In sheet metal forming practice we distinguish five basic modes of deformation. Drawing is a metalworking process that uses tensile forces to stretch metal glass or plastic.

As the metal is drawn pulled it stretches thinner into a desired s. Sheet metal is one of the very convenient ways that is used in metal working and it can be mended and cut into various shapes and dimensions. Deep drawing operation in sheetmetal is a widely used sheet metal forming Operations in the automotive and consumer goods sector to manufacture sheet metal parts.

The die cavity matches the punch and is a little wider to allow for its passage as well as clearance. Deep drawing of sheet metal is performed with a punch and die. Sheet metal drawing and wire bar and tube drawing.

A wide range of products are manufactured with the use of sheet metal making it an essential part of the modern world. Mainly sheet metal process can be divided into three types. The deep-drawing process converts a sheet metal blank.

This mode of deformation is found mostly on smooth bottoms of shallow parts and in hydroforming processes. Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape change. Bending of Tube Stock.

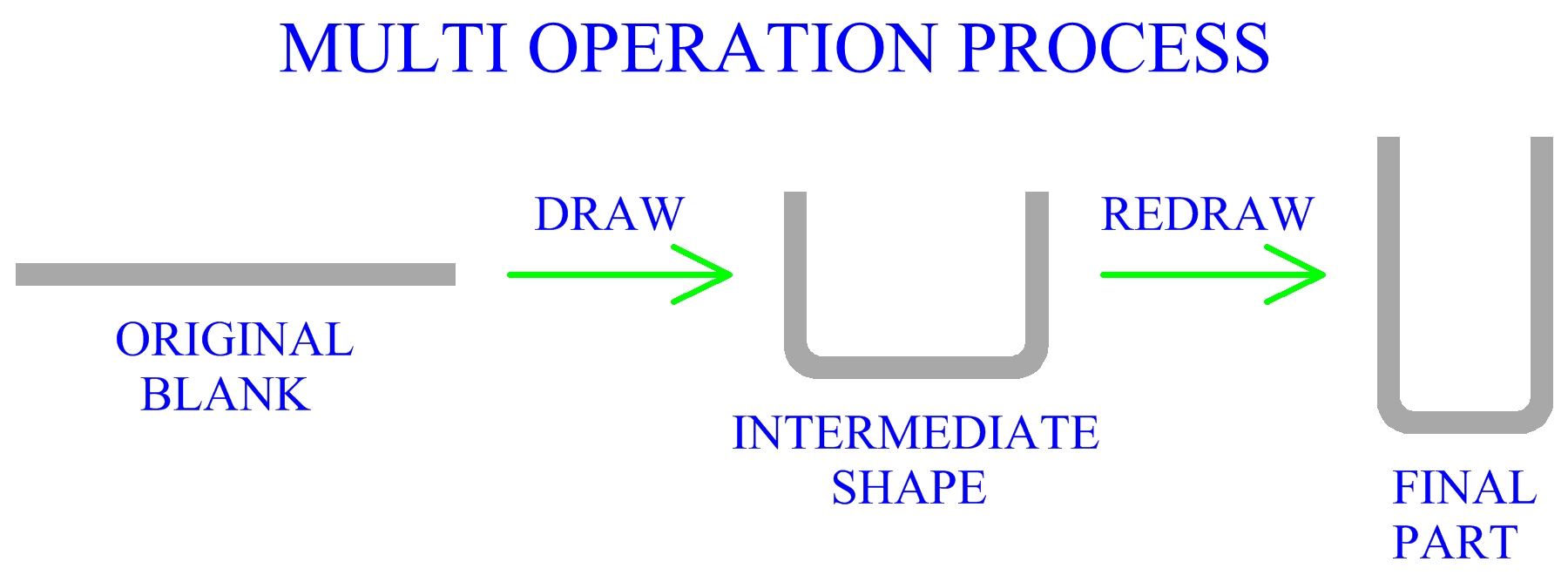

True False Coining is a bulk deformation process also used in sheet-metal work in which fine details in a die are impressed into the. Drawing is classified into two types. The material is expanded in both directions.

For wire bar and tube. Introduction Cutting and forming thin sheets of metal usually performed as cold working Sheet metal 04 164 to 6 mm 14in thick. With the use of the industrial manufacturing process sheet metal is formed by working metal into flat and thin pieces.

This setup is similar to sheet metal cutting operations. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and pushing the metal into the cavity with a punch. Beverage cans ammunition shells automobile body panels.

The first one is sheet metal cutting second one is sheet metal bending or forming and the last one is known as deep drawing. Drawing Sheet metal forming operation used to make cup shaped box shaped or other complex curved hollow shaped parts Performed by placing a piece of sheet metal over a die cavity and then pushing the metal into the opening with a punch. Sheet metal Drawing Operation involves drawing sheet metal parts in a cup-like shape by utilizing a bending press.

The deep drawing process is used to manufacture sheet metal parts in large volumes for various industries.

9 Different Types Of Sheet Metal Operations With Diagram Pdf

Deep Drawing An Overview Sciencedirect Topics

Deep Drawing An Overview Sciencedirect Topics

Deep Drawing Find Suppliers Processes Material

Sheet Metal Forming Process 3 Download Scientific Diagram

Sheet Metal Forming An Overview Sciencedirect Topics

Sheet Metal Tools Cutting Marking Bending Tools

Types Of Drawing Process Wire Drawing Rod Drawing And Tube Drawing Mech4study

Pin On Manufacturing Technology